Standby Generators

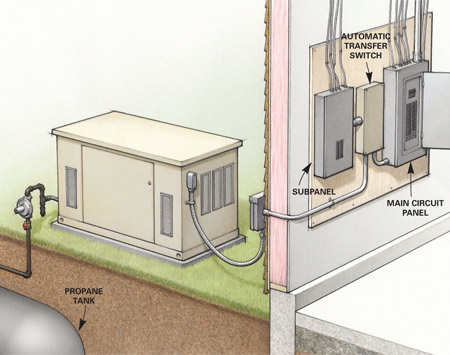

A

standby generator is usually and permanently installed outside your

residence or commercial building and wired directly into your

electrical system. It is used to provide power to some or all of

your circuits during a disruption of utility power. Standby

generators can be fueled by liquid propane, natural gas or diesel

and usually start effortlessly and

automatically.

A

standby generator may cost as little as $2,900 or as much as

$15,000 or more--the greater the power capacity, the higher the

cost. Additional installation costs also apply to your specific

system. Standby generators create from 7,000 to 25,000 watts or

more of power. You'll have to choose a standby generator that

supplies sufficient peak and continuous wattage for the circuits or

appliances you need to power.

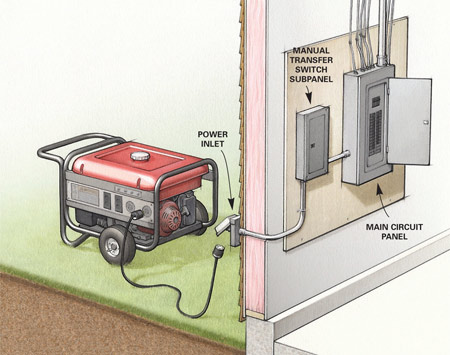

Portable

Generators

Portable power

generators are versatile and used for:

• emergency power at

home

• power in remote locations where

utility power is unavailable or

• recreational purposes, like

boating or camping

Portables can be fueled by gasoline,

liquid propane or diesel and include 120-volt power outlets like

the ones in the walls of your home. When the generator is running,

you can plug appliances and tools directly into these outlets. Some

generators also include 240-volt outlets (that is, the kind of

outlet for an electric dryer or for other large

appliances).

Portable power systems can

range from $1,500 to $3,900 depending on wattage and require

manual starting. Manual transfer switches can also give you the

ability to connect a portable generator to your permanent

electrical system. You can choose the circuits or equipment that

you need to power based on the generator's capacity.

What is the best generator for the money? The installation costs of

portable generators are usually less than that of standby. Factors

such as manual activation and fueling are required to keep the

portable system functioning during an

emergency/outage.

Standby Generator

Maintenance Checklist

Here’s a handy

checklist to help guide you as you work to maintain your standby

generator(s). Be sure to take note of the frequency recommendations

for these maintenance activities.

Weekly

Maintenance

- Run the generator (typically no-load, automatic transfer

switch exercise cycle).

- Verify that the unit ran and has no alarms or

warnings.

- Ensure adequate fuel levels.

- Ensure that the generator is in “Auto” mode, for

automatic startup.

- Check that the circuit breaker is closed.

- Make sure there are no fluid leaks.

Monthly

Maintenance

- Check engine coolant level.

- Check engine oil level.

- Check the battery charger.

Bi-Annual

Maintenance (Schedule maintenance with a certified

technician.)

- Inspect the enclosure.

- Check the battery electrolyte level and specific

gravity.

- Check battery cables and connections.

- Inspect drive belts.

- Inspect the coolant heater.

- Check coolant lines and connections.

- Check for oil leaks and inspect lubrication system hoses

and connectors.

- Check for fuel leaks and inspect fuel system hoses and

connectors.

- Inspect the exhaust system, muffler and exhaust

pipe.

- Check and clean air cleaner units.

- Inspect air induction piping and connections.

- Inspect the DC electrical system, control panel and

accessories.

- Inspect the AC wiring and accessories.

Annual

Maintenance (Schedule maintenance with a certified

technician.)

- Change oil and filter.

- Change the fuel filter.

- Change the air filter.

- Clean the crankcase breather.

- Change spark plugs.

- Check coolant concentration.

- Flush the cooling system (as needed).

- Perform load bank testing.

- Fuel testing & reconditioning (diesel-fueled units

only).

- Remove water from fuel tank (diesel-fueled units

only).